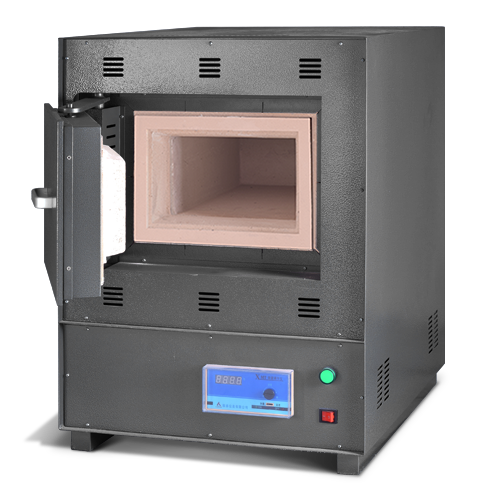

SXⅡ Box type Resistance Furnace(Muffle furnace)

SXⅡ Box type Resistance Furnace(Muffle furnace)

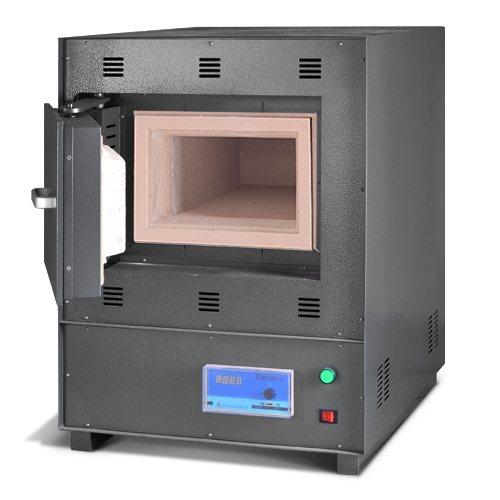

The Kenton manufactured Muffle furnace is suitable for laboratory, industrial, and mining applications, scientific research units for element analysis and measurement, small-scale steel hardening, annealing, tempering of heat treatment for heating, furnaces can also be used for metal, ceramic sintering, dissolution, and analysis of high heating use. Intelligent box type high-temperature oven (resistance furnace).

The heating element uses a unique nickel-chrome filament production process in a new type of furnace designed to withstand high temperatures, offering greater endurance.

More efficient materials for density insulation; digital display, microcomputer control, over-temperature alert.

Technical Parameters:

| Model |

Power (KW) |

Temp range (℃) |

Voltage (V) |

Overall dimension (mm) (H*W*D) |

Packing size (mm) (H*W*D) |

Net weight (KG |

Shiping weight (KG |

| SXⅡ-4-10 | 4 | 1000 | 220 | 640*490*630 | 760*570*710 | 155 | 180 |

| SXⅡ-5-12 | 5 | 1200 | 220 | 640*490*630 | 760*570*710 | 155 | 180 |

| SXⅡ-8-10 | 8 | 1000 | 380 | 780*580*770 | 900*660*850 | 235 | 250 |

| SXⅡ-8-12 | 8 | 1200 | 380 | 780*580*770 | 900*660*850 | 235 | 250 |

More

More

Product introduction:

● This series of high-temperature ovens, also known as resistance furnaces, are ideal for use in laboratories, industrial and mining settings, scientific research units, and small-scale steel hardening, annealing, and tempering heat treatment for heating purposes. Additionally, furnaces can be used for metal sintering, ceramic sintering, dissolution, and analysis involving high heating temperatures.

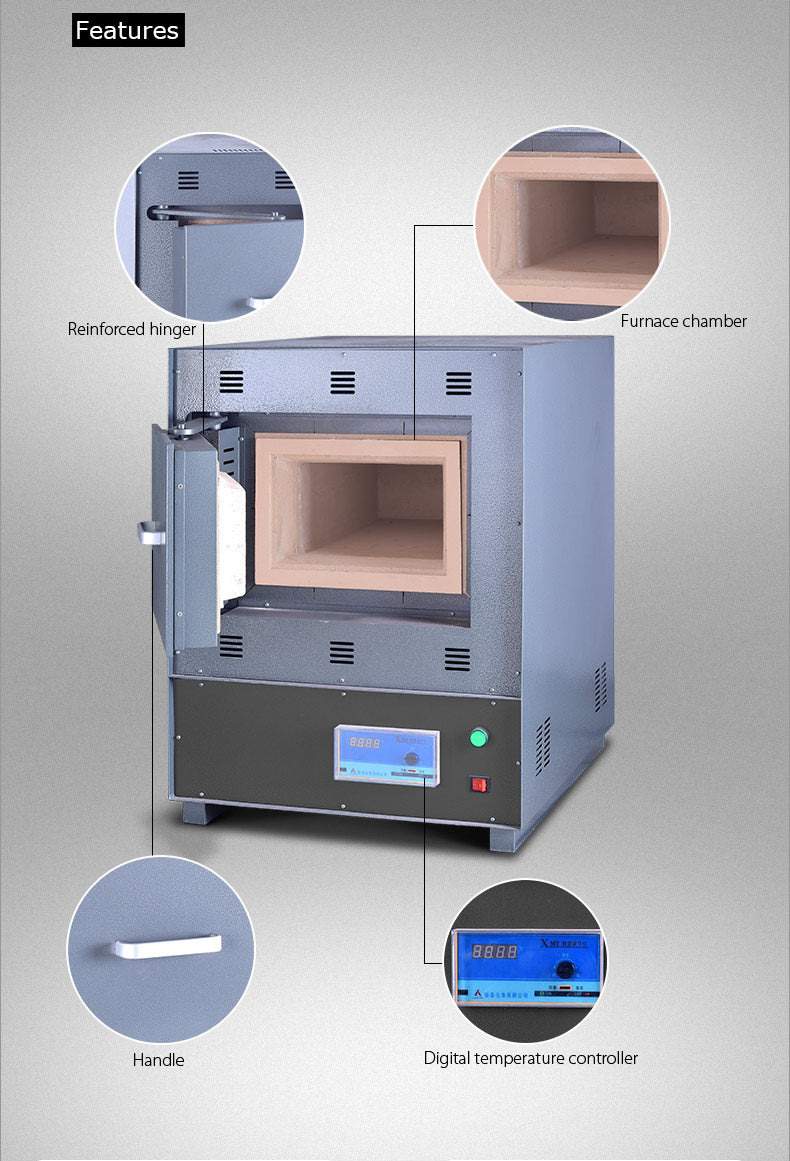

Features:

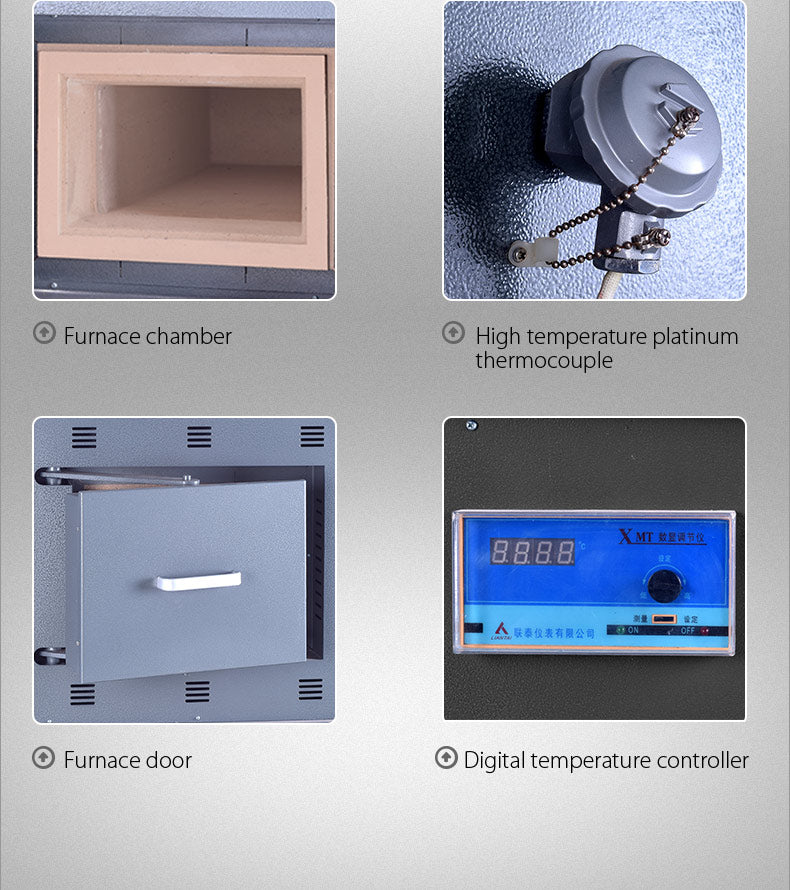

● New kind of high temperature resistant materials studio for furnace; heating element uses unique nickel-chrome filament production methodology.

● To prevent damage from electrical components that may melt at high temperatures, the control component is located in the lower portion of the furnace.

● The furnace and its shell are designed with high density insulation materials, making them more efficient.

● The lever type furnace door has a hallux valgus design for convenient operation.

● The low surface temperature of the furnace shell is achieved by its porous cooling design.

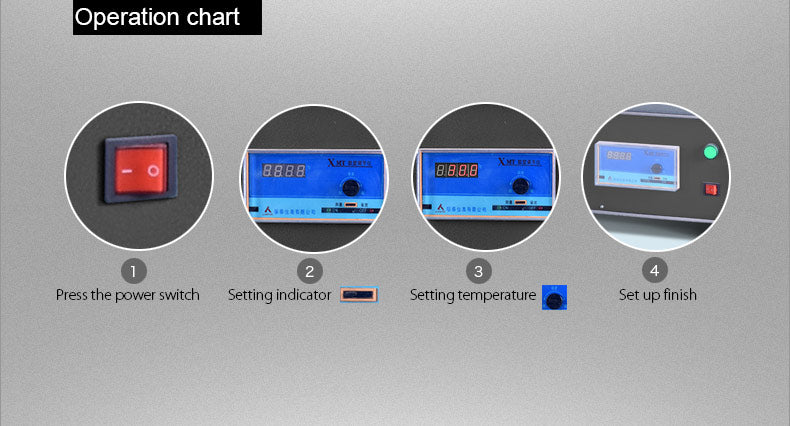

● The temperature control system has a digital display, intelligent PID control technology, high temperature precision, and a temperature alert feature.

● The overall design is both highly practical and unique.

Share

Get help with product selection and ordering

Tel: 0086-020-36246586, 0086-020-36246650, 0086-020-36247961

Fax: 0086-020-36246651

Sales Email: kenton@kentonchina.com

Feedback Email: brian@kentonchina.com

Wechat: guan13189191849